What about this as a mental picture? You’re in front of your driveway, looking at your trailer with a bent axle, and you know you need to get that fixed, but you have no idea where to start. Maybe you’ve already spent a great deal of time looking through a plethora of online catalogues, only to find out you don’t even know what standard trailer axle sizes you need.

Or perhaps you’ve had a negative experience before purchasing an axle that you believed was correct, only to discover it doesn’t fit. This has you sending money for return shipping and waiting longer.

Selecting the proper trailer axle is bewildering, particularly if you have no idea where to start. Trailer owners are generally fed up with problems such as uneven tire wear, poor handling, or sudden failure. These are most frequently the result of the incorrect size or type of axle.

The most aggravating aspect is that these problems have a way of occurring at the worst possible moment, such as when you’re preparing to take the kids on a camping trip or attempting to complete a work project on a deadline.

You’re not purchasing an axle; you’re paying to be safe, relaxed, and capable of getting your work accomplished. You don’t choose the wrong axle to spend money; you spend time away from what matters. It can result in dissatisfied customers, missing family events, or worrying about car trouble in the middle of nowhere.

How to measure an axle for a trailer? It’s easy to measure an axle, but a tiny mistake could cost you money in repairs, time wasted, and even safety while driving. The risk is more than just getting the right part—it’s about preventing a chain of problems that can happen with the wrong choice.

If you have ever struggled to find plain information, feared ordering the incorrect part, or been baffled when comparing axle types and sizes, you are not alone. It is a process replete with technical jargon and conflicting recommendations, and it is easy to second-guess yourself. Most trailer owners are unable to proceed because they do not wish to make a costly error, particularly with parts that may cost hundreds or thousands of dollars.

The truth is, most trailer axle dimension guides assume you already know the basics, so you’re on your own to figure out important information. They throw around words like “spring center” and “hub face” without explaining what these terms mean in your specific application. As you sit there trying to determine if that measurement you took is correct, or if you’ve missed something critical that will ultimately bite you in the butt, they’re laughing all the way to the bank.

How to measure a trailer axle? This blog is designed to dispel fear and misunderstanding by walking you through each step in simple English. It will assist you in avoiding the most common errors and ensure you purchase the correct axle the first time. We will walk you through what to measure, why every measurement is crucial, and how to prevent costly issues that plague many trailer owners.

With the correct information, you can select and measure a trailer axle that best suits your requirements and makes your trailer function efficiently, providing you with the peace of mind that you deserve.

Learning the Fundamentals of Trailer Axles

Before making measurements, you must know what you have. Most costly errors are made because trailer owners are so eager to purchase that they have no idea what to search for in axles and how each will affect their trailer’s performance.

Spending a few minutes learning these basics will save you time, money, and headaches in the future.

What Is A Trailer Axle?

A trailer axle is a central shaft that links the wheels and supports the trailer load. It has the function of distributing the weight and ensuring stability while in motion. You can call it the skeleton of your trailer—if the axle is not working, your trailer is unsafe and unreliable.

The axle doesn’t just keep your wheels stationary; it’s designed to support the moving forces that happen when you’re towing something. As you cruise down the highway, turn, or drive over bumps, your axle is continuously working to keep the wheels aligned, distribute the trailer’s weight evenly, and cushion the road bumps.

That is why choosing the right axle for your purpose is so crucial—it’s not just a case of putting the parts together, but ensuring that they can take the stresses that you’ll be putting on them.

Types of Trailer Axles

Understanding the various types of axles can assist you in deciding what will work for you and how you are going to utilize them.

1. Straight Axle

This is the most popular and simplest axle configuration, going directly from hub to hub. Straight axles are typical for use in utility trailers because they provide typical ground clearance and are usually the least expensive.

They are best for everyday towing when you don’t require special features such as an extremely low deck height. The simplicity of straight axles makes them easier to repair and replace, which is an excellent choice for the majority of trailer owners.

2. Drop Axle

Also referred to as a “dropped axle,” this setup features a bend in the midsection of the frame that lowers the trailer deck closer to the ground. This lower deck position is much easier to load and unload, particularly for heavy machinery, motorcycles, or other heavy loads that are difficult to lift to a higher deck.

Drop axles are usually gauged by the amount of drop they have, 2 to 6 inches. They do lower ground clearance a bit, but they are convenient when easy loading is the issue.

3. Torsion Axle

Torsion axles employ rubber cords or torsion bars within the axle tube rather than leaf springs to suspend. The benefits of this system include a smoother and quieter ride due to independent wheel suspension, lower maintenance due to the absence of grease fittings and moving components, and enhanced handling on rough terrain.

They each work separately, so if one wheel hits a pothole, it won’t affect the other wheel. Torsion axles, though, are generally more costly to buy up front and could be more expensive to fix if they get damaged.

4. Spring Axle

These axles use traditional metal leaf springs located above or below the axle tube for suspension. Spring axles are the most widely employed type on trailers, well-suited to haul heavier weights and demanding road conditions. The leaf spring suspension is robust, long used for decades, and relatively cheap to maintain in good working order.

You can also modify them quite significantly—you can change the spring rate, use additional springs, or modify the suspension to accommodate particular load requirements. They will not provide you with the same smooth ride as torsion axles, but they are robust and can handle heavy loads, which makes them a more appropriate option for severe applications.

Critical Measurements You Should Take

Now that you’ve learned about the various types of axles, let’s have a look at the key measurements you’ll need to measure to know whether your new axle will fit. There are four key measurements—getting one of them wrong could create an axle that won’t fit your trailer.

Let’s consider each measurement and why it is crucial.

Hub Face To Face

This is the measurement from the outside of one hub to the other. It sets the width of the axle and puts the wheels in the correct position under the trailer.

Spring Centre to Spring Centre

Measure from the center of one spring seat to the center of the other. This comes in handy when aligning the axle to the suspension system of the trailer.

Total Length

The total length is from the other spindle tip to this one. It is not necessarily required, but it can be used to verify whether the axle will fit, particularly when the hubs are not present.

Axle Drop

Axle drop is the distance from the centerline of the axle tube to the centerline of the spindle, vertically. Axle drop determines the ride height and ground clearance of the trailer. Drop axles reduce the trailer deck, which makes it easier to load.

Trailer Axle Size Chart

- Axle Capacity (lbs.) Tube Diameter Hub Face (inches) Spring Centre (inches) Common Uses

- 2,000 – 2,200 1.75″ 60 – 72 48 – 60 Small utility trailers

- 3,500 2.375″ 70 – 89 58 – 74 Single axle trailers

- 5,200 – 7,000 3.00″ 85 – 95 70 – 80 Tandem axle trailers

- Always check against your trailer axle sizes and manufacturer’s guidelines.

Equipment Required For Accurate Trailer Axle Measurements

To take precise measurements, you will require some necessary equipment. Start with a measuring tape measuring at least 10 feet, as that should be enough for most axles on trailer measurements.

You will also need a caliper or ruler for measuring smaller items or for taking accurate size measurements. Keep a marker or some chalk handy for marking reference points while taking measurements. You will require a pen and a notebook for writing down all measurements accurately.

Safety gear is essential. Jack stands are important to support the dump trailer safely while taking measurements, and a flashlight allows you to read measurements easily in the dark. Finally, use the camera on your phone to snap reference photos of the axle configuration, which will be extremely helpful when buying replacement parts or describing things to experts.

How to Measure Axles for a Dump Trailer?

The measurement process begins with proper preparation. Park your trailer on a level spot and safely secure it before you start. Remove wheels and tires so you have better access to the axle pieces and can take more precise measurements.

First, measure from one hub face to the other hub face. Place your measuring tape outside one hub and pull it straight to the outside of the other hub. This is the total width of the axle assembly.

Then, measure from spring center to spring center. Locate the center of one of your spring seats and measure to the other center. This is important to ensure the correct alignment of your trailer suspension system.

If you have to measure axle drop, use the caliper or rule and measure the straight distance from the center of the spindle to the center of the axle tube. This will affect the height at which your trailer sits and the ground clearance.

During the process, take meticulous care to record all measurements and double-check each of them. Inaccurate measurements by even a small amount can mean ordering the wrong axle, and that can cause expensive delays and possible safety problems.

Common Mistakes to Avoid

Most frequent mistakes can affect how accurately you measure your axles and wheels for trailers. One frequent mistake is measuring to the wrong reference points, e.g., measuring from spindle ends instead of the hub faces. This will result in you purchasing an axle that does not fit correctly.

Another huge blunder is overlooking the spring center measurements. Several individuals consider only the hub face measurement but tend to ignore the fact that the spring centers must align correctly with the mounting points of the trailer’s suspension.

Employing old or damaged measuring tools can cause huge errors. Always use functional measuring equipment and phase out old equipment that can give different results.

Ensure that you consider axle drop when it counts. It is a measurement taken to ensure the correct ground clearance and the trailer’s proper height.

Measurement with wheels on will give inaccurate readings. Remove the wheels at all times to have easy access to measurement points everywhere.

Choosing the Appropriate Axle for Your Trailer

Selecting an appropriate axle involves a few key factors to consider. First, ensure the limit of the axle’s weight is the same as the overall weight rating of your trailer. Don’t exceed the axle limit, as this will lead to serious issues.

Ensure that your major measurements are consistent with your trailer size. Hub face to hub face, spring center to spring center, and axle drop should all be the same as your trailer suspension and frame configuration. Even slight differences can cause wheel alignment, tire life, and trailer performance problems.

Consider what type of axle you’ll need depending on what you plan to use it for. Straight axles are suitable for general use, but drop axles are ideal if you prefer a low deck height for easy loading. Torsion axles are smoother and require less maintenance, so they’re suitable for heavy use. Spring axles are heavy-duty for heavy loads and rough roads.

If you’re unsure, go and consult a trailer parts axle specialist. They can measure you and recommend the best axle configuration for your application.

Are You Ready To Discover The Ideal Axle For Your Trailer?

How to measure a trailer axle? Precise measuring is the solution to a reliable and safe trailer. Be patient, have the right tools, and double-check your work, and you will select the correct axle for your needs. The right axle means a smoother ride, better handling, and a longer trailer.

By so doing and adhering to these tips, you will be able to provide your trailer with the right axle to safely and efficiently tow.

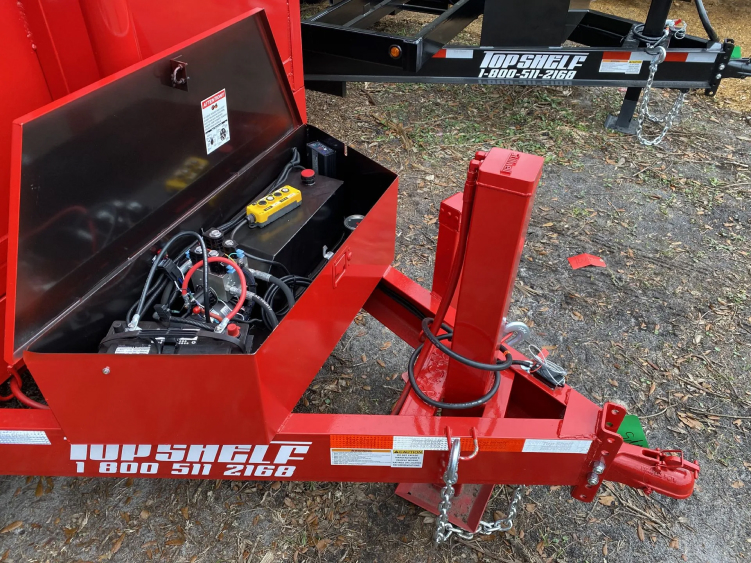

Don’t let doubt keep you off the road. At Top Shelf Trailers, they have the expertise in creating premium trailer axles and components that meet your unique needs.

Their experienced staff can assist you in double-checking your measurements, recommend a proper axle configuration, and get you parts that will have your trailer operating smoothly for years to come. Drop by today and see how professional trailer parts will enhance your towing capacity.

Frequently Asked Questions

1. Where Is The Axle On My Trailer?

Check for a manufacturer’s mark or stamp on the axle tube. It typically indicates the kind of axle, weight capacity, and other information. If you cannot find a label, check the suspension system—torsion axles are equipped with rubber cords, and spring axles employ leaf springs.

2. What Is the Difference between Single and Dual Axles?

Single axles consist of one axle and two wheels, and they are more straightforward to maneuver and less costly to buy. Dual (tandem) axles consist of two axles and four wheels, and they are more stable and can pull heavier trailers.

3. Where Are New Trailer Axles Available?

Replacement axles for trailers can be bought at trailer parts shops, online shops, and from their manufacturers. Always provide the proper measurements and axle details when ordering to ensure that it will fit.

4. Are Trailer Axle Kits, Brakes, And Hubs Included?

Brakes and hubs are sometimes part of some axle kits and sometimes not. Always thoroughly read the product description and ask the supplier about the sale before buying to avoid additional unexpected costs.

5. How to Determine Trailer Axle Weight Capacity?

If you want to determine trailer axle weight capacity, look on the trailer’s axle label or VIN plate for the weight capacity. If you cannot find this, measure the diameter of the axle tube and refer to a size chart or owner’s manual to estimate the capacity.